- FREE Express Shipping On Orders $99+

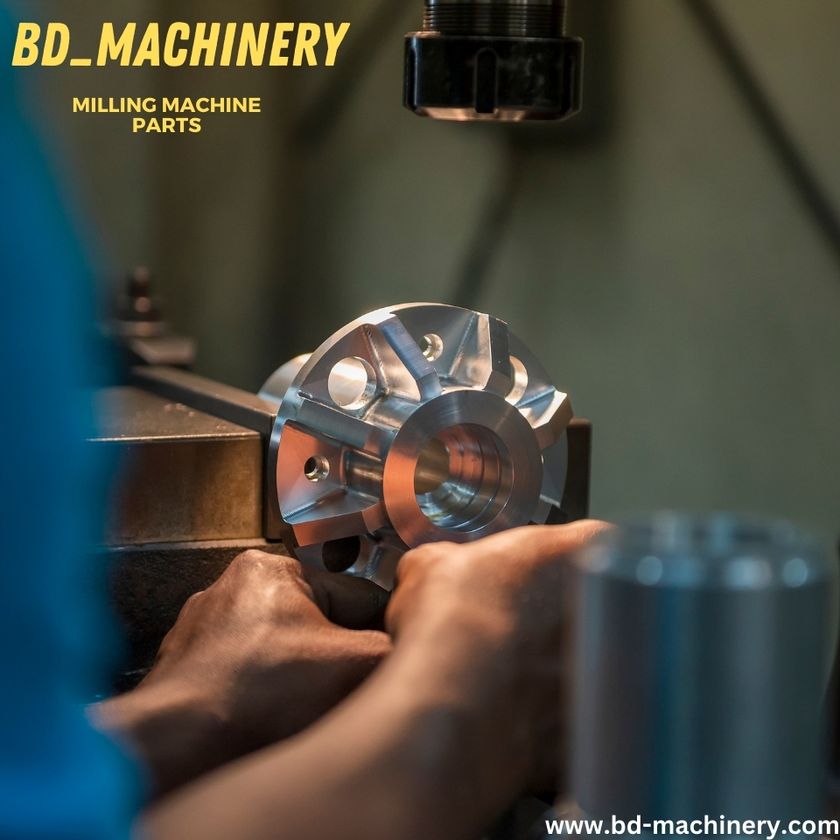

Understanding Milling Machine Parts: A Comprehensive Guide for Beginners

Milling machines are essential tools in the manufacturing industry, used for shaping solid materials. Whether you’re a novice machinist or an experienced professional, understanding the parts of a milling machine is crucial for effective operation and maintenance. This guide provides a detailed overview of the main milling machine parts, helping you to identify and understand their functions.

1. Base and Column

The base is the foundation of the milling machine, providing stability and support for all other components. It is typically made of cast iron to withstand the heavy loads and vibrations during milling operations. The column, mounted on the base, is a vertical structure that supports the machine’s head and spindle.

2. Knee

The knee is a vertically adjustable component attached to the column. It supports the saddle and table, allowing them to move up and down along the column. The knee’s movement is controlled by a vertical knee screw, providing the vertical travel needed for various milling operations.

3. Saddle and Table

The saddle sits on top of the knee and moves horizontally, providing the transverse (Y-axis) motion of the milling table. The table, mounted on the saddle, holds the workpiece and provides longitudinal (X-axis) movement. The table’s movement is facilitated by a lead screw and can be controlled manually or via CNC.

4. Spindle

The spindle is one of the most critical milling machine parts. It is located in the machine’s head and holds and rotates the cutting tool. The spindle speed can be adjusted to suit different materials and cutting requirements. A high-quality spindle ensures precision and smooth operation, essential for achieving accurate cuts.

5. Head

The head houses the spindle, motor, and various speed and feed controls. It can be adjusted vertically and tilted to various angles, allowing for versatile machining operations. The head’s flexibility is particularly useful for complex milling tasks that require angled cuts or drilling operations.

6. Quill

The quill is a cylindrical part that moves the spindle up and down. This movement is known as the quill feed, controlled by a hand wheel or automatic feed mechanism. The quill allows for precise depth control during drilling and milling operations, enhancing the machine’s versatility.

7. Overarm/Overhead Arm

The overarm, found in horizontal milling machines, extends over the column and supports the arbor. The arbor is a shaft that holds the milling cutter in place. The overarm provides additional rigidity and stability to the milling cutter during horizontal milling operations.

8. Arbor

The arbor is a horizontal bar used to hold the milling cutter in horizontal milling machines. It is supported by the overarm and the spindle. The arbor’s length and diameter vary depending on the cutter’s size and the specific milling operation being performed.

9. Control Panel

Modern milling machines often feature a control panel for easy operation. This panel includes switches, dials, and displays for adjusting spindle speed, feed rate, and other settings. In CNC milling machines, the control panel also includes a computer interface for programming and controlling the machine’s movements.

10. Power Feed

The power feed mechanism allows for automatic table movement, providing consistent and precise feed rates. It can be used for both longitudinal and transverse table movements, reducing operator fatigue and improving machining accuracy.

Conclusion

Understanding the milling machine parts is fundamental for efficient operation and maintenance. Each component plays a vital role in the machine’s overall functionality, from the sturdy base and column to the versatile spindle and control panel. By familiarizing yourself with these parts, you can optimize your milling processes, achieve precise cuts, and extend the life of your machine. Whether you’re milling metal, wood, or plastic, this guide serves as a valuable resource for mastering your milling machine.